Figure 1: Loader bucket tooth.

The mining industry relies on heavy-duty equipment to extract valuable resources from the earth. Mining wear parts play a crucial role in the efficiency and longevity of this machinery.

This article will guide you on how to find a reliable supplier of high-quality mining wear parts for your industrial equipment. We'll cover the importance of wear parts, steps to find a reliable supplier, and tips for ensuring a successful long-term partnership.

1. Importance of High-Quality Mining Wear Parts

Mining wear parts are essential components of industrial equipment that are subjected to wear and tear. These parts include ground engaging tools, crusher liners, bucket teeth, cutting edges, and other wear-resistant components. High-quality wear parts provide the following benefits:

● Improved Efficiency: Durable and well-designed wear parts can significantly improve the performance of your mining equipment. This results in increased productivity and reduced downtime.

● Extended Equipment Life: By using top-notch wear parts, you can minimize the wear and tear on your machinery, prolonging its service life and reducing the need for costly repairs or replacements.

● Cost Savings: Although high-quality wear parts may initially be more expensive, their durability and performance can save you money in the long run by reducing maintenance costs and increasing the service life of your equipment.

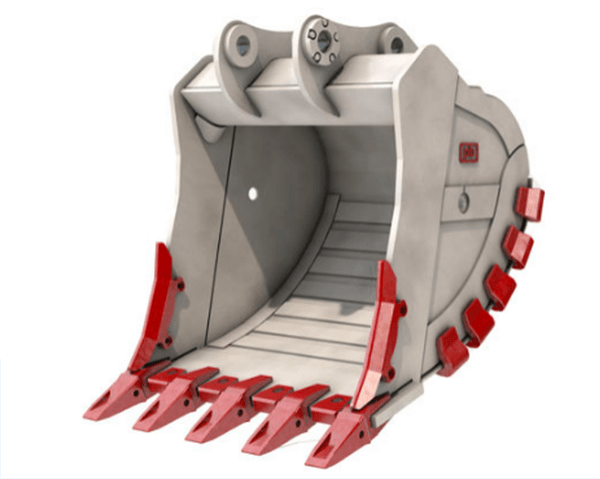

Figure 2: Bucket teeth.

2. Understand Your Needs

The first step in finding a reliable supplier of high-quality mining wear parts is to understand your needs. You should know what type of wear parts you require for your mining equipment, such as excavators, bulldozers, or loaders.

You should also have an idea of the quantity of wear parts you need, as well as their specifications, such as size, material, and hardness. Understanding your needs will help you narrow down your search and make it easier to find a supplier that meets your requirements.

3. 10 Steps to Find a Reliable Supplier

To find a reliable supplier of high-quality mining wear parts, please follow the steps below:

3.1 Research Potential Suppliers

Once you have a list of the wear parts you need, it's time to start researching potential suppliers. A quick online search will yield many results, but it's essential to take the time to research each one thoroughly.

Look for suppliers who have experience in the mining industry and have a reputation for providing high-quality parts. Check their website and read reviews from previous customers. You can also ask for recommendations from other mining companies or industry experts.

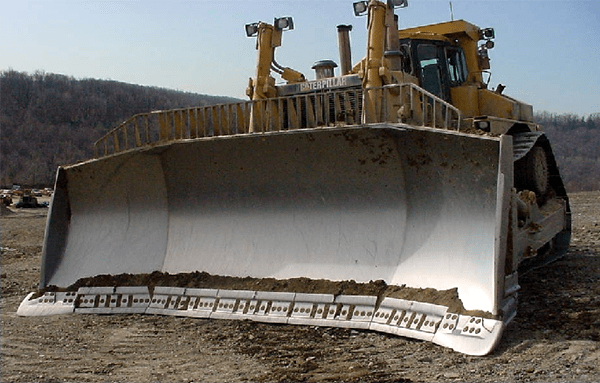

Figure 3: Bucket with various wear parts.

3.2 Check Quality Assurance

When it comes to mining wear parts, quality assurance is crucial. You want to make sure that the parts you are purchasing are of high quality and will stand up to the wear and tear of mining operations.

When researching suppliers, check to see if they have a quality assurance program in place. This can include things like testing and inspection of parts before they are shipped, as well as a warranty or guarantee on the parts they provide.

3.3 Consider Pricing

While quality should be your primary concern, pricing is also an important factor to consider when choosing a supplier. You should look for a supplier that offers competitive pricing without compromising on quality.

Be wary of suppliers that offer extremely low prices as this may be an indication of substandard quality. You should also consider the supplier's payment terms and any discounts or promotions they offer.

Figure 4: Bulldozer blade.

3.4 Consider Delivery Time

The delivery time is another critical factor to consider when choosing a supplier of mining wear parts. Mining operations are time-sensitive, and any delays in the delivery of wear parts can lead to downtime and reduced productivity.

You should ensure that the supplier has a fast and reliable delivery system that can meet your requirements. Ask the supplier about their delivery times and whether they offer expedited shipping options.

3.5 Check Industry Expertise

Look for a supplier with a proven track record in the mining industry. They should have extensive knowledge of the specific wear parts your equipment requires and be familiar with the challenges and demands of your operation.

A supplier with industry expertise will be better equipped to provide tailored solutions that meet your unique needs.

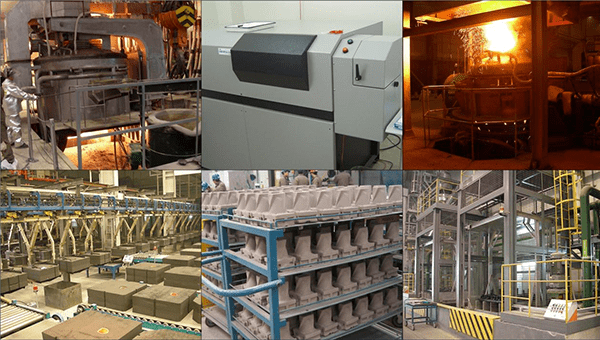

Figure 5: Excavator bucket tooth production.

3.6 Check Warranty

A warranty is an assurance of quality and reliability from the supplier. It is essential to choose a supplier that offers a warranty on their wear parts. The warranty should cover defects in material or workmanship and should provide a replacement or refund if the wear parts fail prematurely.

You should read the warranty terms carefully and ask the supplier about any limitations or exclusions.

3.7 Check Customization Capabilities

Your mining operation may require customized wear parts to suit specific applications or equipment models. A reliable supplier should be able to provide custom solutions tailored to your requirements.

3.8 Check Range of Products

A supplier with a comprehensive range of wear parts for different types of mining equipment will be more likely to meet your needs. This also indicates that they have a better understanding of the industry and can provide a wide range of solutions.

Figure 6: Various wear parts for excavators.

3.9 Check Technical Support and Customer Service

A good supplier will offer excellent customer service and technical support. They should be responsive to your inquiries and provide assistance with product selection, installation, and maintenance.

Look for suppliers that offer ongoing support, such as training and troubleshooting, to ensure that your equipment performs optimally.

3.10 Ask for Samples and Certifications

Before committing to a supplier, ask for samples of their parts to ensure they meet your specifications and quality requirements. You can also ask for certifications or testing reports to verify the quality of the parts. This will give you peace of mind knowing that you are getting high-quality parts that will last.

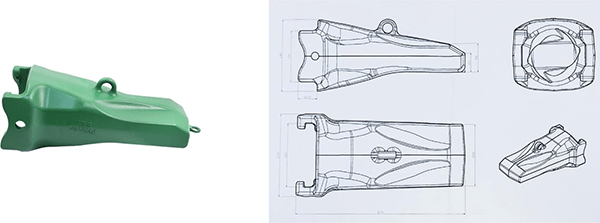

Figure 7: A&S custom tooth design drawing.

4. Tips for Ensuring a Successful Long-Term Partnership

Once you've identified a potential supplier, consider these tips to foster a successful long-term partnership:

● Establish Clear Communication: Open and frequent communication is crucial for maintaining a strong business relationship. Share your needs, expectations, and any concerns with your supplier. This will help them understand your requirements better and provide the best possible solutions.

● Negotiate Terms and Conditions: Don't be afraid to negotiate the terms and conditions of your partnership, including pricing, payment terms, and delivery schedules. A reliable supplier will be willing to work with you to establish a mutually beneficial relationship.

● Provide Feedback: Share your experiences with the supplier, both positive and negative. This will help them improve their products and services, ultimately benefiting your operation.