Figure 1: Wear parts for excavators.

Wear parts, also known as wearing parts or consumable parts, refer to the components of machinery and equipment that are subject to wear and tear over time due to friction, impact, and other forms of stress. These parts need to be replaced periodically to ensure the continued performance of the machine.

Wear parts play a critical role in ensuring that machinery and equipment operates efficiently and effectively, reducing downtime and maintenance costs. In this article, we will discuss the types of machinery and equipment that require wear parts.

Mining Equipment

Mining equipment is designed to operate under the most challenging conditions imaginable, including high heat, pressure, and vibrations. Components such as crusher liners, drill bits, conveyor belts, and shaker screens are just a few examples of the wear parts required by mining equipment.

Due to the severity of the conditions, mining wear parts often need to be replaced more frequently than those used in other industries.

Some common types of mining equipment that require wear parts include:

Excavators:

Excavators are heavy equipment used for digging and moving large amounts of earth and rock. Wear parts used in excavators include bucket teeth, cutting edges, and side cutters. These components are exposed to abrasive materials such as rocks and gravel, which can cause significant wear and tear over time.

Figure 2: Bucket tooth.

Bulldozers:

Bulldozers are used for pushing large quantities of soil, sand, and debris. Wear parts used in bulldozers include cutting edges, blades, and end bits. These components are exposed to abrasive materials and high-impact forces, making them prone to wear and tear.

Haul Trucks:

Haul trucks are used to transport large quantities of materials from mining sites to processing plants. Wear parts used in haul trucks include tires, brakes, and suspension components. These components are exposed to heavy loads and constant vibrations, which can cause significant wear and tear over time.

Construction Equipment

Construction equipment is also subjected to extreme conditions, such as exposure to abrasive materials like rocks and concrete. Excavators, bulldozers, backhoes, loaders, and other construction vehicles rely on wear parts such as tracks, rollers, sprockets, and hydraulic pumps to perform their duties.

Failure to replace these components can lead to reduced efficiency, increased maintenance costs, and even safety hazards.

Some common types of construction equipment that require wear parts include:

Figure 3: mini-excavator.

Agricultural Equipment

Agricultural equipment is subject to harsh conditions, including exposure to dirt, dust, and debris, as well as heavy use in demanding environments. As a result, many components of agricultural equipment require regular replacement, including blades, teeth, belts, chains, and bearings.

For example, combine harvesters require frequent replacement of their cutting blades and teeth, while tractors may need new belts and chains.

Some common types of agricultural equipment that require wear parts include:

Tractors:

Tractors are used for plowing, tilling, and planting fields. Wear parts used in tractors include plowshares, discs, and harrow teeth. These components are exposed to abrasive materials such as soil and rocks, which can cause significant wear and tear over time.

Harvesters:

Harvesters are used for harvesting crops such as grain, fruits, and vegetables. Wear parts used in harvesters include blades, teeth, and chains.

Sprayers:

Sprayers are used for applying pesticides and fertilizers to crops. Wear parts used in sprayers include nozzles, valves, and hoses. These components are exposed to harsh chemicals, which can cause significant wear and tear over time.

Figure 4: Sprayer in farmland.

Industrial Machinery

Industrial machinery encompasses a wide range of equipment used in manufacturing and other industrial processes. This includes everything from food processing machines to printing presses to textile equipment.

Depending on the application, wear parts for industrial machinery may include gears, bearings, belts, chains, and cutting tools. These components must be replaced regularly to ensure the smooth operation of the machinery and prevent downtime.

Some common types of manufacturing equipment that require wear parts include:

Conveyors:

Conveyors are used for transporting materials and products from one location to another. Wear parts used in conveyors include belts, chains, and bearings. These components are exposed to constant stress and friction, which can cause significant wear and tear over time.

Mixers:

Mixers are used for mixing and blending materials in manufacturing processes. Wear parts used in mixers include blades, paddles, and agitators.

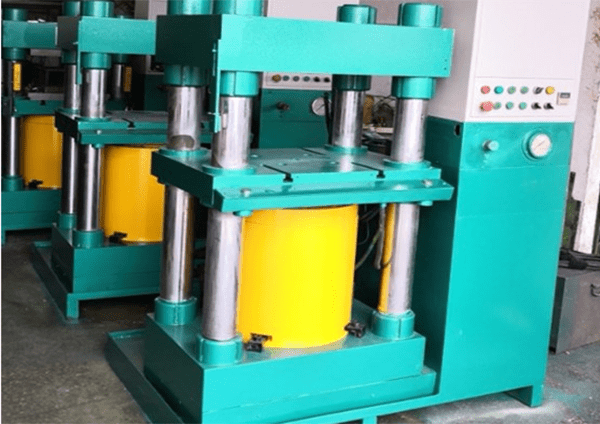

Presses:

Presses are used for shaping and forming materials in manufacturing processes. Wear parts used in presses include dies, punches, and springs. These components are exposed to high-pressure and high-temperature conditions, which can cause significant wear and tear over time.

Figure 5: Presses.

Transportation Equipment

Transportation equipment includes vehicles used for transporting people and goods, such as cars, trucks, buses, and trains, requiring wear parts to function properly. Some examples include brake pads, tires, spark plugs, and oil filters.

Neglecting to replace these components can result in reduced performance, decreased fuel efficiency, and even safety hazards on the road.

Some common types of transportation equipment wear parts include:

Tires:

Tires are one of the most critical wear parts in transportation equipment. Wear-resistant materials such as rubber and high-performance plastics are used to improve the longevity and reliability of tires.

Brakes:

Brakes are used for slowing and stopping transportation vehicles. Wear parts used in brakes include brake pads, rotors, and calipers.

Engine Components:

Engine components, such as pistons, bearings, and valves, are critical wear parts in transportation vehicles. Wear-resistant materials such as steel and ceramics are used to improve the longevity and reliability of engine components.

Figure 5: Car engine.

Medical Equipment

Even medical equipment requires wear parts. For example, surgical instruments such as scalpels and forceps must be sharpened or replaced periodically to maintain their precision. Other medical equipment that may require wear parts includes hospital beds, wheelchairs, and prosthetic limbs.

Conclusion

In conclusion, wear parts are an essential component of many different types of machinery and equipment. From agricultural and construction equipment to mining and industrial machinery, wear parts play a critical role in ensuring the continued performance of these machines.

Regular replacement of these components is necessary to prevent breakdowns, reduce maintenance costs, and promote safety. By understanding which types of machinery require wear parts, individuals and businesses can take proactive steps to ensure that their equipment operates efficiently and effectively for years to come.